What's the fastest way to extract useable CAD, simulated, stitched 3D models with 2D patterns from an e-commerce photo? Completely editable and resizable? With LA VIPÈRE's AI, it's not a hard nor time-consuming task anymore.

Summary: LA VIPÈRE is an AI-powered fashion design platform that can extract production-ready sewing patterns and 3D models directly from e-commerce photos. The system analyzes reference images and detailed descriptions to generate mathematically accurate 2D patterns, complete 3D simulations with realistic physics, and fully graded production files. This breakthrough enables designers to recreate or adapt designs from photos in minutes instead of weeks, with simulation-ready assets, production patterns, and instant automated grading. The technology combines computer vision, generative AI, computational geometry, and 3D simulation to reverse-engineer garment construction from visual references.

Why LA VIPÈRE's Pattern Extraction is Revolutionary

From Photos to Production in Minutes: Traditional pattern making requires weeks of manual drafting, multiple sampling rounds, and expensive revisions. LA VIPÈRE AI analyzes e-commerce photos and generates production-ready patterns in minutes, complete with 3D simulation validation before any physical sampling.

Complete Pattern Engineering from Visual Reference: The AI doesn't just approximate shapes—it constructs precise pattern engineering including dart placement, seam allowances, grain lines, notches, and all technical specifications required for production. Complex features like curved darts, cutouts, pleats, and style lines are automatically calculated and validated in 3D.

Simulation-Ready Assets: Every pattern generated by LA VIPÈRE comes with full 3D simulation capability, allowing designers to see exactly how the garment will drape, fit, and move before cutting any fabric. This eliminates the costly trial-and-error of physical sampling.

Instant Automated Grading: Once the base pattern is extracted, LA VIPÈRE automatically generates graded patterns for all sizes, maintaining proper fit and proportions across the entire size range. This process that traditionally takes days happens instantly.

Production-Ready Export: Patterns export in industry-standard formats (DXF, SVG) compatible with all cutting machines and manufacturing systems. Files include all technical specifications, measurements, and construction notes required for production.

The Challenge: Recreating Complex Designs from Photos

Have you ever wanted to replicate a design from a photo? Either to create variations, start with a similar base, or simply understand how the pattern is constructed?

Until now, this meant hours of manual pattern drafting, multiple sampling rounds, and expensive revisions. Even experienced pattern makers struggle to reverse-engineer complex garments from photos alone.

But that's changing. Fast.

The Experiment: House of CB Dress Reconstruction

We ran an experiment with a complex dress from House of CB to test LA VIPÈRE's AI capabilities. Here's the side-by-side comparison of the original e-commerce photo versus our AI-generated 3D model:

Reference photo from House of CB (left) vs. AI-generated pattern and 3D simulation (right) created in minutes by LA VIPÈRE

This dress is not easy to construct, even for an AI. It features:

- Darted cap sleeves with curved darts for shaping

- Back cutouts with a mini waistband connecting the bodice and skirt

- Front cutout with curved waist seam and underarm cut details

- Front side panels with curved waist darts

- Box pleats - single pleat on front panel, double pleats on back panels

- Pleat centers aligned perfectly to panel seams

All of these features were constructed perfectly from a prompt and image. The full rendering was obtained in just a few minutes.

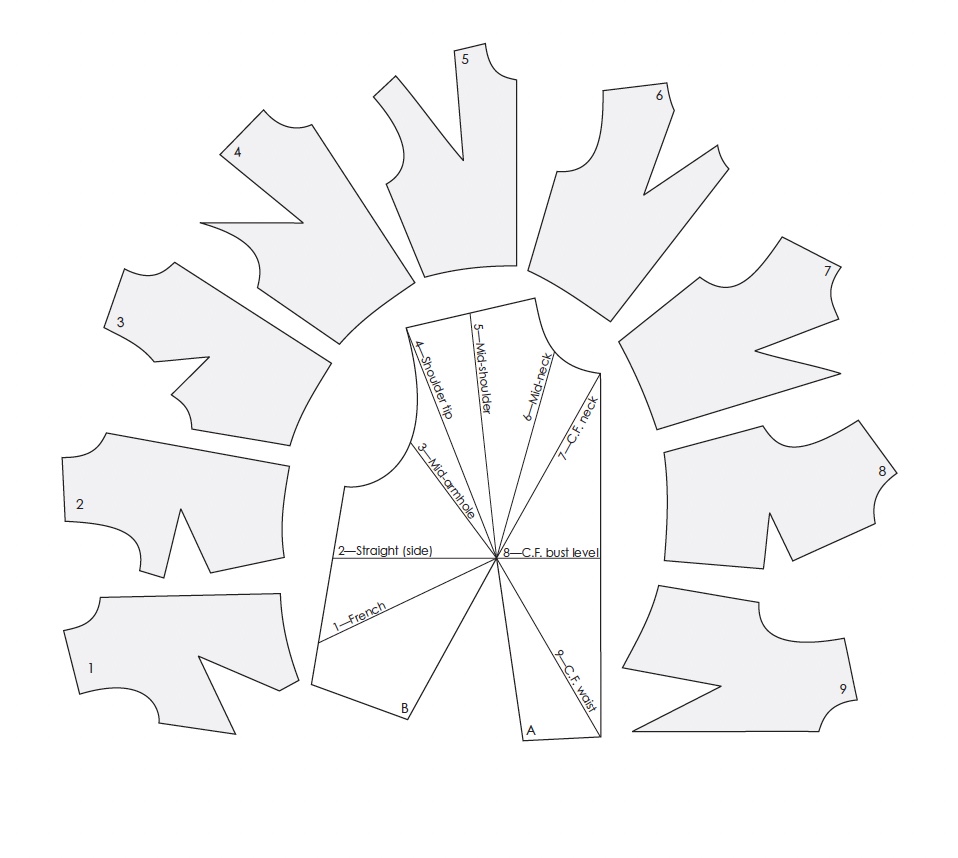

Multiple angles of the AI-generated 3D model showing accurate construction of all design features including cap sleeves, cutouts, pleats, and curved seams. View original post on LinkedIn

Why This is a Big Deal

Last year, AI could only combine a few basic blocks together. Now it's constructing full patterns from scratch with crazy accuracy.

The implications are massive:

- Design iteration speed: Test variations in minutes instead of weeks

- Cost reduction: No expensive physical samples for initial design validation

- Knowledge preservation: Capture and recreate design details without manual pattern making expertise

- Creative freedom: Experiment with modifications and adaptations risk-free

- Educational tool: Study how complex garments are constructed by seeing the actual patterns

How It Works: From Photo to Production Pattern

Step 1: Upload Your Reference Photo

Start with any e-commerce photo or fashion image. The higher quality the photo, the more details the AI can extract, but even standard product photos work remarkably well.

Step 2: Describe the Design

Provide a detailed description of the garment construction. For our House of CB dress, the prompt was:

"Create a dress with darted cap sleeves, front and back box pleats, back cutouts and front side panels with curved waist darts."

The more specific your description, the more accurate the result. Include details about:

- Sleeve type and construction

- Bodice features (darts, seams, cutouts)

- Skirt construction (pleats, gathers, panels)

- Special details (waistbands, collars, closures)

Step 3: AI Pattern Generation

LA VIPÈRE's geometric AI engine combines computer vision and computational geometry to:

- Analyze the photo for construction details

- Interpret your description using geometric AI that understands garment construction

- Generate mathematically accurate 2D pattern pieces

- Calculate dart placement, seam allowances, and grain lines using precise geometric algorithms

- Validate pattern engineering rules through computational geometry

Step 4: 3D Simulation Validation

Instantly see your garment in 3D with realistic physics simulation. Check:

- Fit and drape

- Seam alignment

- Proportion and balance

- Movement and comfort

Step 5: Export Production Files

Download your patterns in industry-standard formats:

- DXF/SVG files for cutting machines

- Complete grading for all size ranges

- Technical specifications and measurements

- 3D files for virtual showrooms and marketing

The Advantages: Why Use AI for Pattern Extraction?

1. Simulation-Ready Assets

Every pattern comes with full 3D simulation capability. See exactly how your garment will look and fit before cutting any fabric. Iterate designs virtually and validate fit across different body types.

2. Production Patterns

Not just approximations—these are production-ready patterns with all technical specifications, seam allowances, notches, and grain lines. Export directly to your cutting machines or send to manufacturers.

3. Instant Automated Grading

Generate graded patterns for your entire size range automatically. LA VIPÈRE maintains proper proportions and fit across all sizes, a process that traditionally takes days of manual work.

4. Speed and Efficiency

What used to take weeks of pattern making and sampling now takes minutes. Test multiple design variations, adapt existing designs, and iterate rapidly.

5. Cost Reduction

Eliminate expensive physical sampling in early design stages. Validate designs in 3D before cutting fabric, reducing waste and development costs.

6. Knowledge Accessibility

You don't need years of pattern making training to recreate complex designs. The AI handles the technical pattern engineering while you focus on creative decisions.

Use Cases: Who Benefits from Pattern Extraction?

Fashion Designers

Rapidly prototype designs inspired by runway looks or create variations of existing styles. Test different proportions and details without manual pattern drafting.

Emerging Brands

Build your first collection without hiring expensive pattern makers. Extract patterns from inspiration images and adapt them to your brand aesthetic.

Manufacturers

Quickly analyze client reference images and provide accurate tech packs and costing. Reduce communication errors and speed up sample development.

Fashion Students

Learn garment construction by studying how complex designs are engineered. Understand pattern making principles through practical examples.

Vintage Reproduction

Recreate vintage designs from historical photos. Adapt classic silhouettes to modern sizing and production methods.

The Technology Behind It

LA VIPÈRE combines multiple advanced technologies:

Computer Vision & Geometric AI

AI analyzes photos to extract construction details, proportions, and design features. The system recognizes pattern elements like darts, pleats, seams, and style lines. Design descriptions are interpreted through geometric AI that understands spatial relationships and garment engineering principles, not blind language models.

Computational Geometry

Mathematical algorithms ensure patterns are geometrically sound, developable, and follow garment engineering principles. Every pattern is constructed using precise geometric rules derived from differential geometry and surface theory.

3D Simulation

Physics-based cloth simulation validates patterns in 3D, showing realistic drape, fit, and movement.

Automated Grading

Intelligent grading algorithms generate size ranges while maintaining proper fit and proportion across all sizes.

Limitations and Best Practices

While LA VIPÈRE's AI is powerful, here are some tips for best results:

- Use clear photos: Multiple angles help the AI understand construction

- Be specific in descriptions: Include technical details about darts, seams, and construction methods

- Validate in 3D: Always check the 3D simulation before production

- Iterate if needed: Refine your description or adjust generated patterns as needed

- Understand pattern making basics: While AI does the heavy lifting, understanding fundamentals helps you describe and validate designs

The Future of Fashion Design

The ability to extract patterns from photos represents a fundamental shift in how fashion design works. What once required specialized skills and weeks of work can now happen in minutes with AI assistance.

But this isn't about replacing pattern makers—it's about augmenting creativity and accelerating the design process. Designers can focus on creative decisions while AI handles technical pattern engineering.

As the technology improves, we'll see even more accurate extractions, better handling of complex constructions, and seamless integration with manufacturing workflows.

The question isn't whether AI will transform fashion design—it's how quickly you'll adopt it to stay competitive.