We visited a garment factory to understand the pattern making process in a real production environment. Our mission was to document how sample production actually works—from the moment a design image arrives to the final mass production.

What we discovered was a complex, time-consuming 12-step process that involves multiple rounds of iteration, physical sampling, washing, and fitting. Each step adds time and cost to the production pipeline.

This article documents the complete sample production workflow we observed, the bottlenecks at each stage, and how LA VIPÈRE accelerates this process and fits into the production pipeline.

The 12-Step Sample Production Process

Here's the complete workflow we documented during our factory visit:

Step 1: Design Reception

An image of the design is received by the pattern maker, along with necessary adjustments and specifications. The pattern maker must interpret the design from a 2D image and translate it into a production-ready pattern.

Time: Variable, depending on design complexity

Bottleneck: Interpretation of design intent from 2D images can be ambiguous

Step 2: Base Pattern Selection

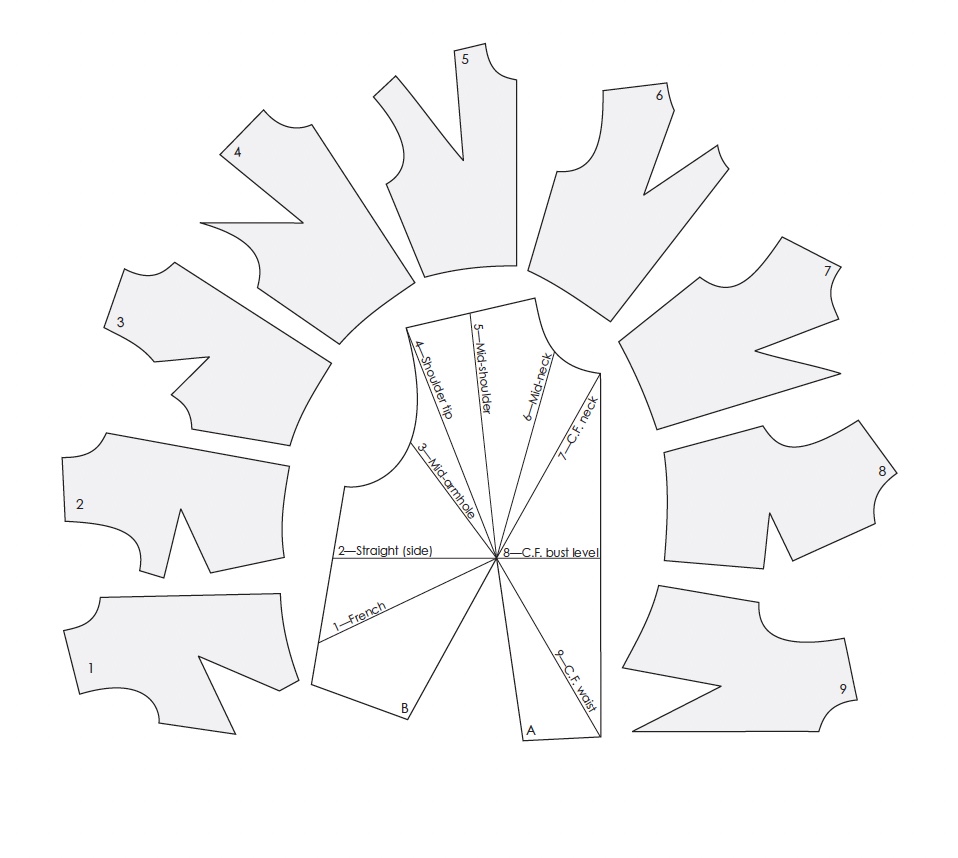

The pattern maker chooses from an existing library of base silhouettes, selecting the silhouette that matches the current design most closely. This base pattern serves as the foundation for all modifications.

Time: 15-30 minutes

Bottleneck: Finding the right base pattern can be time-consuming if the library is large or poorly organized

Step 3: Pattern Development

The pattern maker performs the necessary adjustments and design additions on this base silhouette such that it matches the expected design. This involves modifying darts, seams, and adding design features.

Time: 2-8 hours, depending on design complexity

Bottleneck: This is where most of the pattern making work happens. For complicated designs, it was clear how inefficient the pattern making process was without visualization or fast iteration. We've seen pattern makers and sample makers argue over pleat length and width, then just wing it.

Step 4: Production Preparation

The pattern maker prepares the resulting design for production. This is a multi-part process:

- Define layers: A garment might be constituted of one inner shell and one outer shell. The components for each of these are exported separately. For example, the parts for the inner lining are placed in the same layer, and the parts for the main fabric are in a different layer. They also specify how many component copies are needed for each one.

- Make the grading: Using the final pattern, they adjust it to each size in the size range. This means they move each point from the pattern in a specific direction with a specific offset, consistent with their grading rules.

- Export measurements: They take measurements from key points of the pattern and export them in an Excel measurement sheet. This is useful for both sampling and production.

- Export the pattern in 2D: This includes specifying shrinkage percentage so that the final pattern is scaled accordingly.

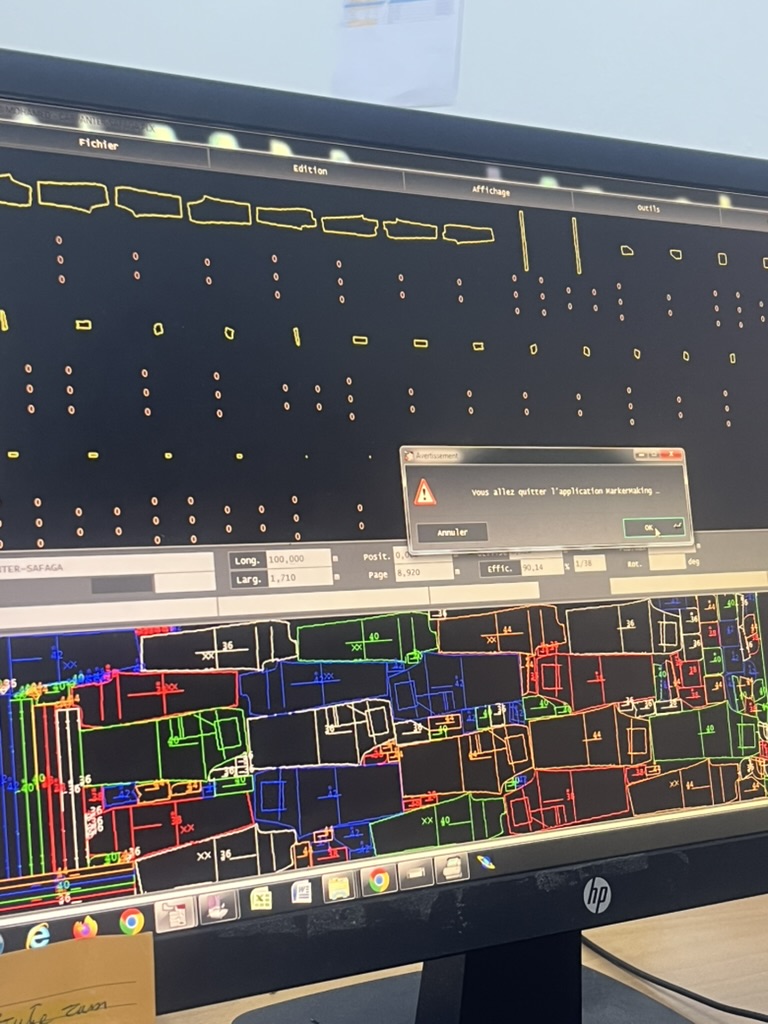

- Optimal placement: Run an algorithm that automatically finds the optimal placement of pattern pieces in 2D to minimize fabric usage, all while respecting constraints (e.g., certain pieces cannot change direction while others can). This is manually specified by the pattern maker in the software.

Time: 1-3 hours

Bottleneck: Manual measurement entry is time-consuming and error-prone. Pattern makers still have to fill in measurement tables manually.

Step 5: Pattern Printing

Once the pattern has been prepared and optimally laid out, it is printed using a plotting machine. The pattern is printed on paper at full scale.

Time: 15-30 minutes

Bottleneck: Physical printing adds time and cost to the process

Step 6: Quality Check

Perform additional check on the measurements from the plotted pattern by taking measurements from it in 2D and comparing them to what has been saved in the software to avoid mistakes. This is a manual verification step.

Time: 15-30 minutes

Bottleneck: Manual measurement verification is time-consuming and can miss errors

Step 7: Sampling Room

The printed pattern, together with the fabric, goes into the sampling room. This is where the physical sample will be created.

Time: Setup time: 15-30 minutes

Bottleneck: Physical transfer of materials between departments

Step 8: First Sample Creation

The garment sampler makes the first sample:

- First lays the plotted pattern on top of the fabric and cuts it with a cutting machine.

- Moves on to sewing machines and starts sewing.

Time: 2-6 hours, depending on garment complexity

Bottleneck: Physical sample creation is time-consuming and requires skilled labor

Step 9: Washing

After sewing, the garment goes to washing. This might take days, depending on the washing requirements and factory capacity.

Time: 1-3 days

Bottleneck: Washing is a significant time bottleneck that can't be accelerated

Step 10: First Fitting

After the garment has been washed, it's back to the sampling room where the first fitting occurs. A model or fit mannequin tries on the garment, and fit issues are identified.

Time: 30-60 minutes

Bottleneck: Fit issues discovered at this stage require going back to Step 3, creating a loop that can repeat multiple times

Step 11: Adjustments

After fitting, there are adjustments to be made—for example, if the size doesn't fit correctly, or if a design feature didn't look good in real life. All these are expressed by the collection manager, and then the pattern is adjusted.

Time: 1-4 hours for pattern adjustments, then the process repeats from Step 3

Bottleneck: This is where the iterative loop happens. Developing the pattern purely in 2D was incredibly painful. The samples would take time to make. And after the sample is made and the fit is tried on, if it wouldn't fit, the pattern makers have to find the mistake, correct the pattern, which is again resampled. This can happen 2-5 times for complex designs.

Step 12: Mass Production

After the final pattern has been validated, it goes into mass production. Here, multiple sizes are produced and optimized for fabric usage together.

Time: Production begins

Bottleneck: Only reached after multiple iterations of Steps 3-11

The total time: A single sample production cycle can take 1-2 weeks, and with multiple iterations for fit adjustments, the entire process can take 3-6 weeks or more for complex designs. This is the critical bottleneck in the design-to-production pipeline.

The Bottlenecks: Where Time and Cost Accumulate

From our observations, the major bottlenecks in the sample production process are:

1. Pattern Development (Step 3)

This is where most of the time is spent. Pattern makers work in 2D CAD without visualization, making it difficult to predict how the pattern will look and fit in 3D. For complicated designs, pattern makers and sample makers often have to "wing it" because they can't visualize the result.

2. Iterative Loop (Steps 3-11)

The most significant bottleneck is the iterative loop between pattern development and fitting. If the fit isn't right, the entire process repeats:

- Pattern adjustment (1-4 hours)

- Pattern preparation (1-3 hours)

- Printing and quality check (30-60 minutes)

- Sample creation (2-6 hours)

- Washing (1-3 days)

- Fitting (30-60 minutes)

This loop can repeat 2-5 times for complex designs, adding weeks to the timeline.

3. Manual Processes

Several steps require manual work that could be automated:

- Manual measurement entry

- Manual quality checks

- Manual pattern adjustments based on fit feedback

4. Physical Constraints

Some steps are inherently time-consuming:

- Washing takes 1-3 days

- Physical sample creation takes 2-6 hours

- Physical pattern printing adds time and cost

How LA VIPÈRE Accelerates the Sampling Process

LA VIPÈRE accelerates the sample production process by addressing the key bottlenecks at each stage:

Accelerating Pattern Development (Step 3)

Traditional pattern development in 2D CAD takes 2-8 hours and requires pattern makers to work without visualization, clicking around interfaces and manually moving points. LA VIPÈRE changes this:

- Instant pattern generation: Generate production-ready patterns in minutes, not hours, from just a prompt and an image

- All classical 2D tools automated: Use all the tools from traditional 2D pattern making—fullness, darts (curvy and straight), multiple darts—all accessible through simple prompts, no clicking around interfaces

- 3D visualization: See how the pattern will look in 3D before creating a physical sample. View real 3D data that belongs to the pattern, rotate it, zoom in, and view from different angles

- No manual measurement entry: Measurements are automatically calculated and exported

Time savings: Pattern development time reduced from 2-8 hours to minutes, with instant 3D visualization that eliminates guesswork. All classical 2D pattern making tools are available through simple prompts—no clicking around interfaces or manually moving points.

Eliminating the Iterative Loop (Steps 3-11)

The biggest time savings comes from reducing the iterative loop. Traditional workflows require multiple rounds of:

- Pattern adjustment → Sample creation → Washing → Fitting → Repeat

LA VIPÈRE reduces this loop by:

- 3D visualization before sampling: Users can see how the pattern will look in 3D before creating physical samples. They can rotate the 3D view, zoom in, and view from different angles to see the real 3D data that belongs to the pattern

- Instant pattern adjustments: If adjustments are needed, patterns can be regenerated instantly with new parameters using simple prompts

- Predictive accuracy: Our mathematical foundation ensures patterns are production-ready from the first generation, reducing the need for multiple iterations

Time savings: Reducing 2-5 iteration cycles to often just 1-2 saves 2-4 weeks per design. Instead of 3-6 weeks for sample production, designs can be validated and ready for production in days.

Automating Manual Processes (Step 4)

LA VIPÈRE automates several manual processes:

- Automatic measurement calculation: No manual measurement entry required

- Automatic grading: Size grading is handled automatically based on mathematical rules

- Automatic optimal placement: Pattern pieces are automatically optimized for fabric layout

- Automatic quality checks: Our system validates pattern geometry automatically

Time savings: Production preparation time reduced from 1-3 hours to automatic, with no manual data entry required.

Streamlining Physical Processes

While we can't eliminate physical processes like washing and sample creation, we can reduce the number of times they're needed:

- Fewer samples needed: With 3D validation, the first physical sample is much more likely to be correct, reducing the need for multiple samples

- Better first samples: Patterns are production-ready from the first generation, so samples require fewer adjustments

Where LA VIPÈRE Fits in the Production Pipeline

LA VIPÈRE fits into the production pipeline at multiple stages:

Stage 1: Pattern Development (Steps 1-3)

LA VIPÈRE accelerates pattern development by:

- Generating patterns instantly from design images and prompts

- Providing 3D visualization before physical sampling—users can see real 3D data, rotate it, and view from different angles

- Automating measurement calculations and pattern preparation

Input: Design image + specifications

Output: Production-ready pattern with 3D visualization

Stage 2: Pre-Sample Visualization

Before creating physical samples, LA VIPÈRE provides:

- 3D visualization showing real 3D data that belongs to the pattern

- Interactive 3D view that users can rotate, zoom, and view from different angles

- Visual preview of how the garment will look

Result: Users can see exactly how their patterns will look in 3D before creating physical samples, reducing the need for multiple iterations

Stage 3: Pattern Refinement

If adjustments are needed after the first sample, LA VIPÈRE enables:

- Instant pattern regeneration with adjusted parameters using simple prompts

- Rapid iteration without going through the full sampling cycle

- 3D visualization of adjustments before creating a new sample—users can see the real 3D data, rotate it, and view from different angles

Result: Faster refinement cycles, fewer physical samples

Stage 4: Production Preparation (Step 4)

LA VIPÈRE automates production preparation:

- Automatic grading for all sizes

- Automatic measurement sheet generation

- Export in multiple formats for different CAD systems

Result: Production-ready patterns with all necessary information included

The pipeline integration: LA VIPÈRE fits seamlessly into existing factory workflows. Patterns generated by LA VIPÈRE can be exported in formats compatible with factory CAD systems (like Lectra), printed using existing plotting machines, and used in the same sampling and production processes. The difference is speed and accuracy: what used to take weeks now takes days, and what used to require multiple iterations now often works on the first try.

The Impact: From Weeks to Days

Here's the impact LA VIPÈRE has on the sample production timeline:

Traditional Workflow Timeline

- Pattern development: 2-8 hours

- Production preparation: 1-3 hours

- Printing and quality check: 30-60 minutes

- Sample creation: 2-6 hours

- Washing: 1-3 days

- Fitting: 30-60 minutes

- First cycle: 3-5 days

- Iterations (2-5 cycles): 6-20 days

- Total: 3-6 weeks

LA VIPÈRE Workflow Timeline

- Pattern generation: Minutes

- 3D validation: Automatic

- Production preparation: Automatic

- Printing and quality check: 30-60 minutes (same)

- Sample creation: 2-6 hours (same)

- Washing: 1-3 days (same)

- Fitting: 30-60 minutes (same)

- First cycle: 3-5 days

- Iterations: Often eliminated or reduced to 1 cycle

- Total: 3-7 days (often first sample is correct)

The result: Sample production time reduced from 3-6 weeks to 3-7 days, with higher accuracy and fewer iterations. This acceleration directly addresses the pattern-making bottleneck that slows down the entire design-to-production pipeline.

Conclusion: Accelerating the Pipeline

The sample production process we documented is complex and time-consuming, with multiple bottlenecks that add weeks to the design-to-production timeline. The biggest bottleneck is the iterative loop between pattern development and fitting, which can repeat multiple times for complex designs.

LA VIPÈRE accelerates this process by:

- Generating production-ready patterns in minutes instead of hours, using all classical 2D pattern making tools (fullness, darts, multiple darts) accessible through simple prompts

- Providing 3D visualization before physical sampling—users can see real 3D data, rotate it, and view from different angles, eliminating guesswork

- Automating manual processes like measurement entry and pattern preparation

- Reducing the need for multiple iteration cycles through predictive accuracy

- Fitting seamlessly into existing factory workflows

The result is a dramatic acceleration of the sample production process: from 3-6 weeks to 3-7 days, with higher accuracy and fewer physical samples required. This directly addresses the pattern-making bottleneck that slows down the entire design-to-production pipeline.

For creative brands and manufacturers operating in fast-paced environments, this acceleration means faster time-to-market, lower sampling costs, and the ability to iterate on designs more quickly. LA VIPÈRE doesn't just automate pattern making—it accelerates the entire production pipeline.