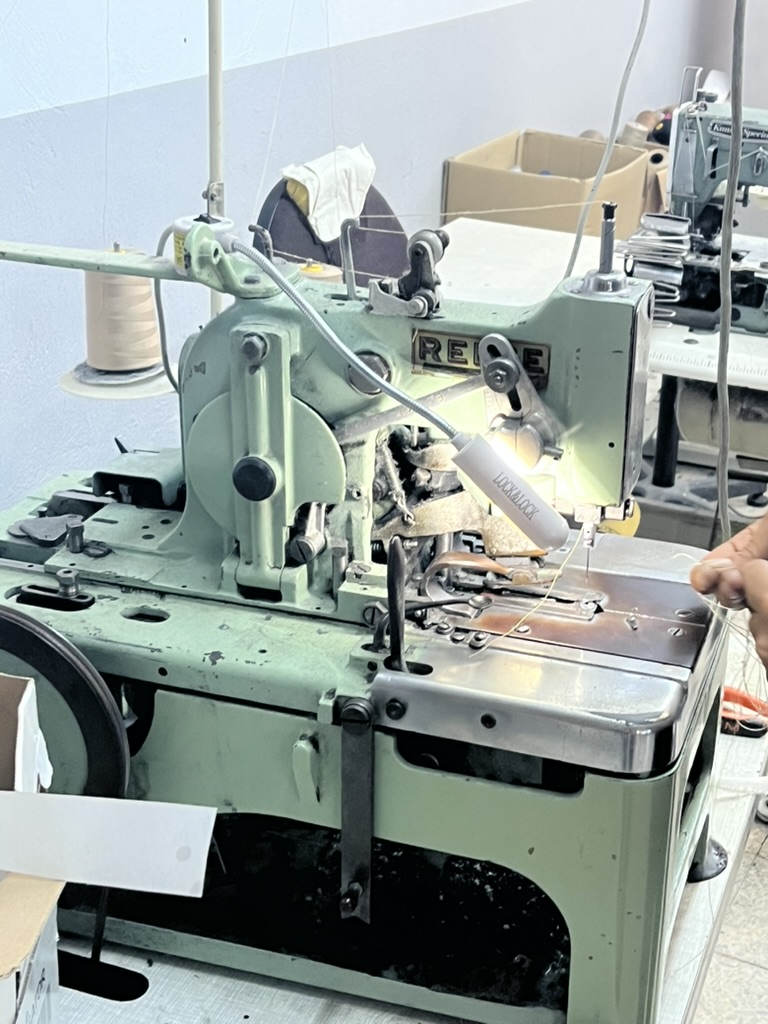

We visited a garment factory to understand the pattern making process in a real production environment. On our first day, we sat in the pattern makers' office and immediately noticed something: they were working on Lectra, a purely 2D CAD system.

I asked a question that had been on my mind: "Why don't you use any 3D software, like CLO3D or Style3D?"

The answer was honest and revealing: "We haven't learned it at university." To their credit, they were actively looking for training. But this highlighted a fundamental problem: the gap between what's taught in fashion education and what's available in the industry.

One pattern maker jokingly added: "Lectra has a 3D feature as well. It's just that nobody uses it."

This experience made us realize: factories are struggling with 3D adoption not because the tools don't exist, but because of deeper systemic issues. Here's what we discovered.

The Reality: 2D CAD Still Dominates Factory Floors

Looking at the interface, it appeared to be software developed in the 1980s. I decided not to judge by appearance alone—functionality matters more than aesthetics. But as I've learned through the years, this is often a bad heuristic. And this case was no exception.

The pattern makers we met were working entirely in 2D. They had access to 3D tools, but they weren't using them. This isn't unique to this factory—it's a pattern we see across the industry.

The reality: Pattern makers in factories are still working primarily in 2D CAD systems, not because 3D tools don't exist, but because they haven't been trained to use them. This creates a significant barrier to adopting more efficient workflows.

Why 3D Tools Remain Underutilized

During our stay, I kept asking myself: Why do pattern makers still not use 3D tools at the pattern construction phase?

We received several revealing answers:

1. The Education Gap

The most honest answer: "We did not learn it in university." This highlights a critical issue: fashion education hasn't kept pace with available technology.

Some people, especially those coming from the tech world, underestimate how hard it is for non-tech enthusiasts to deal with new software. Learning a new 3D CAD system requires significant time investment, and pattern makers who were trained in 2D systems often don't have the resources or support to make that transition.

This is the whole premise of the new AI revolution: interfaces should become obsolete, and you shouldn't need to learn new software for every need.

2. The Interface Problem

As an individual, I hate interfaces. If an interface is simple, I'll use it. If it's not, I prefer to use code. This sentiment is shared by many pattern makers who find 3D software interfaces complex and unintuitive.

Traditional 3D CAD tools like CLO3D and Style3D require users to:

- Learn complex 3D positioning and manipulation

- Spend significant time on 3D simulation setup

- Understand 3D visualization and rendering concepts

- Navigate steep learning curves that can take months to master

For pattern makers who are experts in 2D pattern construction, this represents a significant barrier. They're being asked to learn an entirely new skill set, when what they really need is validation and speed—not another complex tool to master.

3. Functional Limitations and Workflow Disruption

Another answer we received: "There are things that you can do in 2D CAD software that you cannot do in 3D CAD software."

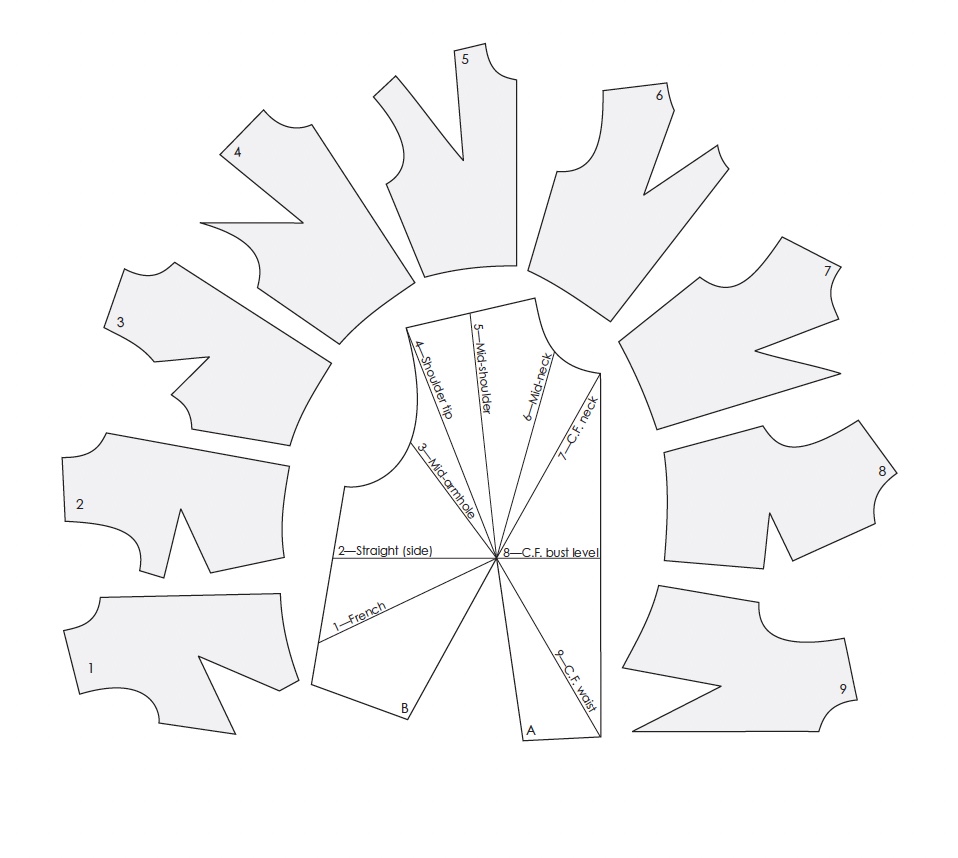

This is true. Traditional 2D CAD has advantages for certain tasks:

- Base pattern development: Starting from a base pattern to develop new designs is much easier in traditional 2D CAD. All properties of the base pattern are preserved, and you develop each piece on its own.

- Export flexibility: At export time, each piece can be selected separately, sized, and associated with different fabrics.

- Optimal placement: After the pattern has been developed, graded, and exported, optimal placement of pattern pieces on the fabric layout is more seamless. You can select different sizes in a single layout, add degrees of freedom to certain pieces (like symmetry), which increases the chances of finding better placement.

- Precision and control: 2D CAD gives pattern makers direct control over every point, line, and curve in the pattern, which is essential for production-ready patterns.

Pattern makers don't want to give up these advantages. They need 2D power, but they also need 3D validation. The problem is that existing tools force them to choose between one or the other.

4. The File Format Problem

One of the most frustrating experiences we had was with file exports. There is no common data format for fashion files. Each software uses its proprietary extension.

There are standards—AAMA, ASTM—but work on these has been discontinued. And if you have any real-life experience, you'll find out that it's not seamless.

We're still struggling to get patterns exported from CLO3D into Lectra. And we know: if we don't do it, our patterns will never be used in production.

The factory had its own set of tools that were interoperable within their ecosystem. Unfortunately, it was a somewhat closed ecosystem with many difficulties in importing and exporting pattern files across different software. We still could not make any AAMA or ASTM-DXF patterns work on their Lectra version.

The barrier: File format incompatibility creates a significant barrier to workflow efficiency. Pattern makers are locked into their software ecosystem, making it difficult to adopt new tools or collaborate across different systems.

The Cost of Staying in 2D

While 2D CAD has its advantages, staying purely in 2D comes with significant costs:

- No visualization: Pattern makers can't see how the garment will look in 3D until they make a physical sample

- Iterative trial and error: Developing patterns purely in 2D is incredibly painful. The samples take time to make. And after the sample is made and the fit is tried on, if it wouldn't fit, the pattern makers have to find the mistake, correct the pattern, which is again resampled.

- Inefficiency for complex designs: For complicated designs, it was clear how inefficient the pattern making process was without visualization or fast iteration. We've seen pattern makers and sample makers argue over pleat length and width, then just wing it.

- Manual measurement entry: Pattern makers still have to fill in measurement tables manually. This is time-consuming and error-prone.

- No fit validation: Without 3D simulation, there's no way to validate fit before creating physical samples, leading to multiple rounds of sampling and adjustment.

Pattern makers need the power of 2D CAD for pattern construction, but they also need 3D visualization for speed and accuracy. The question is: how do you get both without the complexity?

LA VIPÈRE: The Perfect Blend of 2D Power and 3D Visualization

This is exactly why we're building LA VIPÈRE. We've created a solution that bridges the gap between 2D pattern construction power and 3D visualization—without forcing users to learn complex 3D software.

2D Power, Preserved

LA VIPÈRE understands that pattern makers need the precision and control of 2D CAD. Our AI generates patterns using all the classical tools from 2D pattern making—but automated and accessible through a simple prompt, no clicking around interfaces or manually moving points.

All the tools you know from traditional 2D pattern making are available:

- Fullness: Add fullness where needed for design and fit

- Darts: Create curvy darts, straight darts, or multiple darts—all the dart variations you need

- Multiple darts: Use as many darts as your design requires

- All classical 2D tools: Every tool from traditional 2D pattern making is available and automated

- Production-ready patterns: Patterns are generated with all the precision and detail needed for manufacturing

- Export flexibility: Patterns can be exported in multiple formats, with full control over sizing, layers, and fabric associations

- Full control: Every point, line, and curve is mathematically precise and production-ready

The difference? Instead of spending hours clicking around interfaces and manually moving points, you simply describe what you want in a prompt. All the complex pattern making work happens automatically in the background.

3D Visualization, Automated

But we don't stop at 2D. LA VIPÈRE automatically generates 3D visualization, so users can see how their patterns will look in 3D without the complexity of traditional 3D software:

- No 3D positioning required: Users don't need to learn how to position patterns in 3D space. Our AI handles all 3D visualization automatically.

- Real 3D data: Users see true 3D data that belongs to the real pattern—not a simulation, but the actual 3D representation of their pattern

- Interactive visualization: Users can rotate the 3D view, zoom in, and view from different angles to see exactly how the pattern will look

- Instant preview: Get instant 3D previews of how patterns will look, without needing to understand 3D software interfaces

- No steep learning curve: Users can generate production-ready patterns with 3D visualization from their very first use, with no training required

The advantage: LA VIPÈRE gives pattern makers the best of both worlds: all the classical 2D pattern making tools (fullness, darts, multiple darts) accessible through simple prompts, and instant 3D visualization so they can see exactly how their patterns will look—all without requiring them to learn complex 3D software or spend time on 3D positioning.

How We Automate 3D Visualization

Traditional 3D CAD tools require users to manually:

- Position patterns in 3D space

- Configure rendering settings

- Wait for visualizations to generate

- Interpret 3D results

LA VIPÈRE automates all of this. Our AI:

- Automatically generates 3D visualization: Our system automatically creates 3D visualization from the pattern, showing the true 3D data that belongs to the real pattern

- Provides interactive 3D view: Users can rotate, zoom, and view from different angles to see exactly how the pattern will look

- Instant visual feedback: 3D visualization is generated automatically as part of the pattern generation process, so users can see their patterns in 3D immediately

This means pattern makers can focus on what they do best—creating beautiful, well-fitting garments—while our AI handles all the complex 3D visualization in the background. They get to see exactly how their patterns will look in 3D, with full control to rotate and view from any angle.

Solving the File Format Problem

We also understand the frustration of file format incompatibility. That's why LA VIPÈRE is built to work with multiple formats:

- Multiple export formats: Patterns can be exported in formats compatible with various CAD systems

- Seamless integration: Our patterns are designed to work within existing factory workflows

- Production-ready: Exported patterns are immediately usable in production, with all necessary information included

We're committed to making our patterns work in real production environments, not just in our own system.

The Future: Democratizing 3D Validation

The pattern making industry is ready for transformation, but it needs tools that:

- Don't require extensive training: AI-native interfaces that understand natural language and design intent, eliminating the need to learn complex software

- Preserve 2D power: Maintain all the advantages of traditional 2D CAD for pattern construction

- Provide automated 3D visualization: Generate 3D visualization automatically, showing real 3D data that users can rotate and view from different angles

- Work with existing workflows: Integrate seamlessly with factory production processes

- Handle file format complexity: Export to multiple formats and work with various CAD systems

This is exactly what LA VIPÈRE provides. We're not just creating another pattern making tool—we're building an AI-native platform that combines all the classical 2D pattern making tools (accessible through simple prompts) with instant 3D visualization, all without requiring users to learn complex 3D software.

Our mission: AI will not only create new technologies, but it will also democratize access to those technologies. Pattern makers shouldn't need to learn complex software interfaces or struggle with file format incompatibilities. They should be able to focus on what they do best: creating beautiful, well-fitting garments. With LA VIPÈRE, they get all the classical 2D pattern making tools (fullness, darts, multiple darts) accessible through simple prompts, and instant 3D visualization showing real 3D data they can rotate and view from any angle—all automated, all accessible, all from day one.