LA VIPÈRE's AI generates production-ready patterns instantly from design descriptions or reference images, eliminating manual drafting.

Choosing the right pattern making software is one of the most critical decisions for fashion professionals. The tools you use directly impact time-to-market, design flexibility, fit accuracy, and competitive positioning. Here's our comprehensive comparison of the leading pattern making platforms in 2025, based on real factory experience and manufacturer partnerships.

About the Author: This comparison is written by the LA VIPÈRE team, who have spent extensive time on manufacturing floors, in pattern making offices, and working directly with industrial pattern making teams. We have visited garment factories, documented the complete sample production process, and are currently running pilot programs with manufacturers implementing direct image-to-plotter workflows. Major fashion brands are actively requesting workflow integrations with LA VIPÈRE for both their design teams and pattern making departments.

Real-World Manufacturing Experience

This comparison isn't based on marketing materials or feature lists. We've spent extensive time on factory floors and in pattern making offices, understanding the real challenges brands and manufacturers face.

What We've Learned from Manufacturing Floors

Through our factory visits and partnerships, we've documented the complete garment production process from concept to mass production. Read about our firsthand experience: How Garment Sampling Works in a Factory.

The critical bottlenecks we identified:

- Pattern making capacity constraints: Design teams waiting days or weeks for pattern makers to translate concepts

- Multi-size validation delays: Each size requiring separate grading, validation, and 3D setup

- Iteration costs: Design changes requiring complete pattern rework, making exploration prohibitively expensive

- Fit accuracy challenges: Limited ability to validate fit across size ranges before physical sampling

- Time-to-market pressure: Manual workflows extending development cycles by weeks or months

These aren't theoretical problems. They're the daily reality we observed in pattern making offices. Learn more about why factories struggle with current tools: Why Factories Struggle with 3D Adoption.

Current Pilot Programs

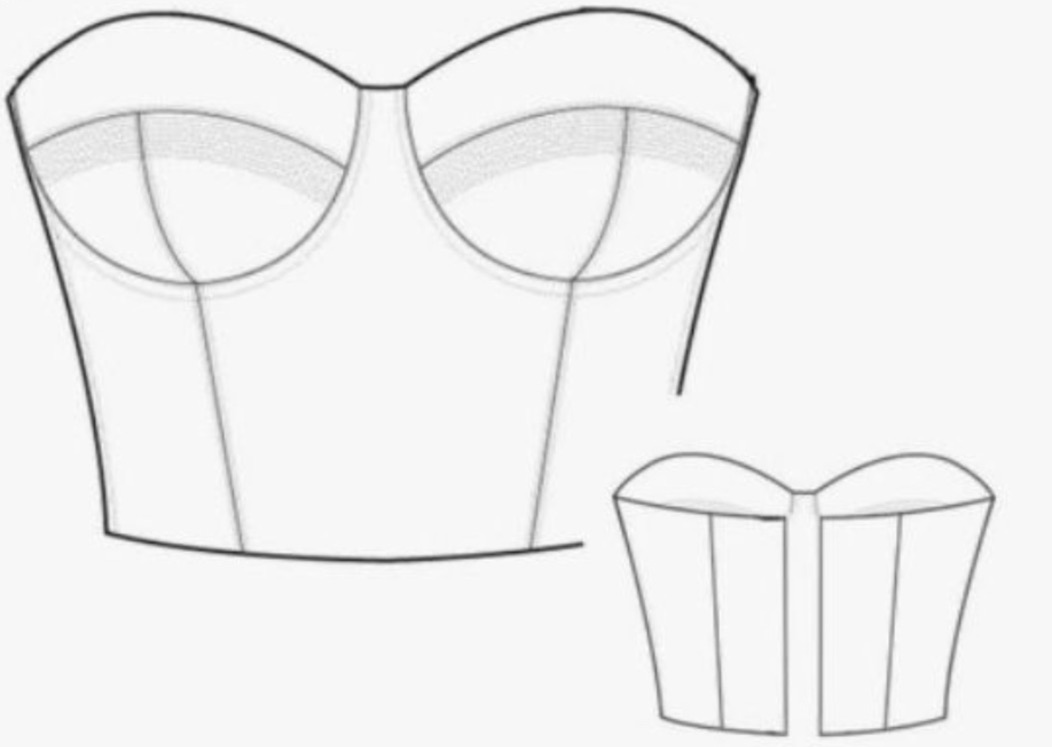

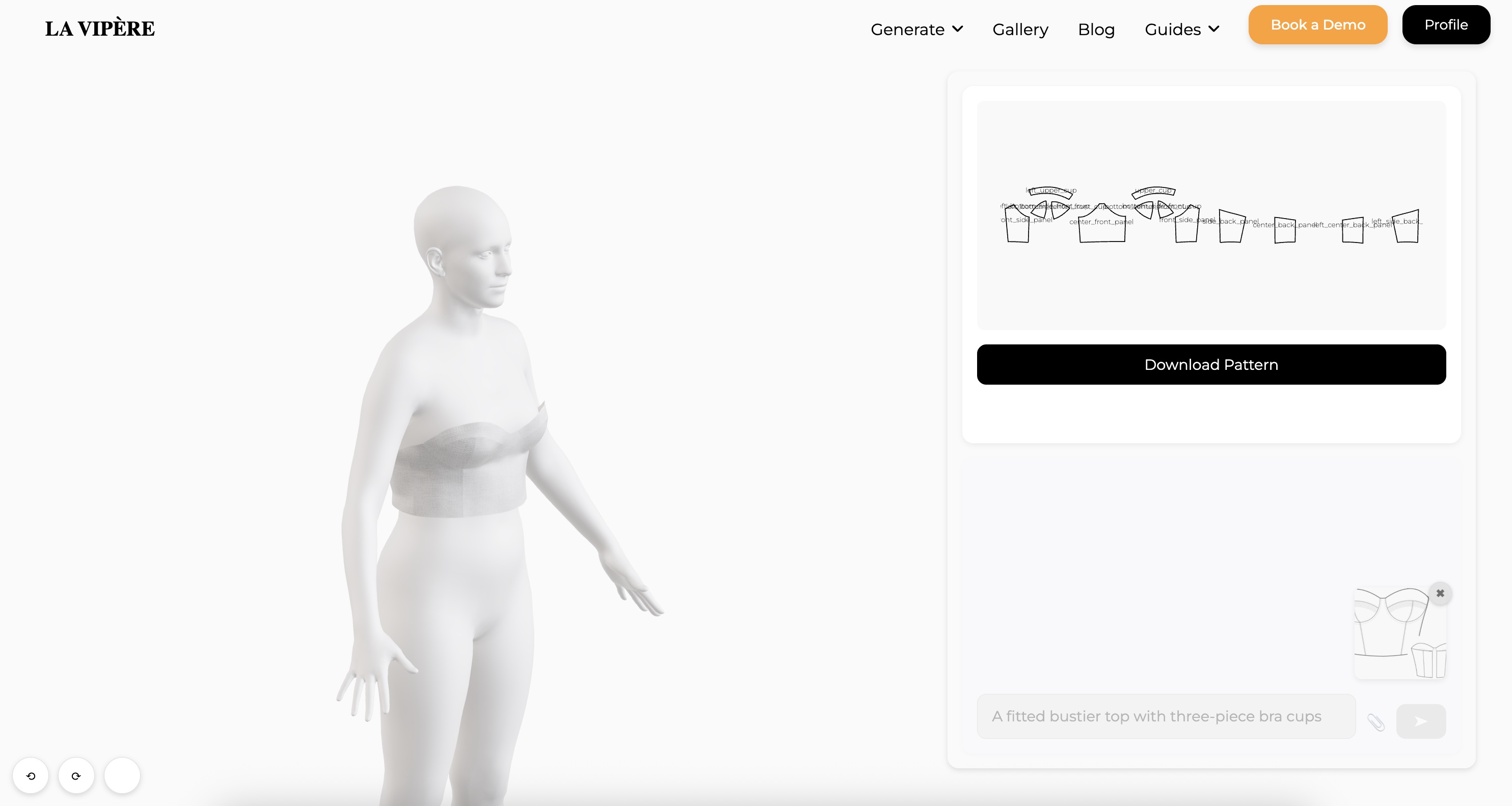

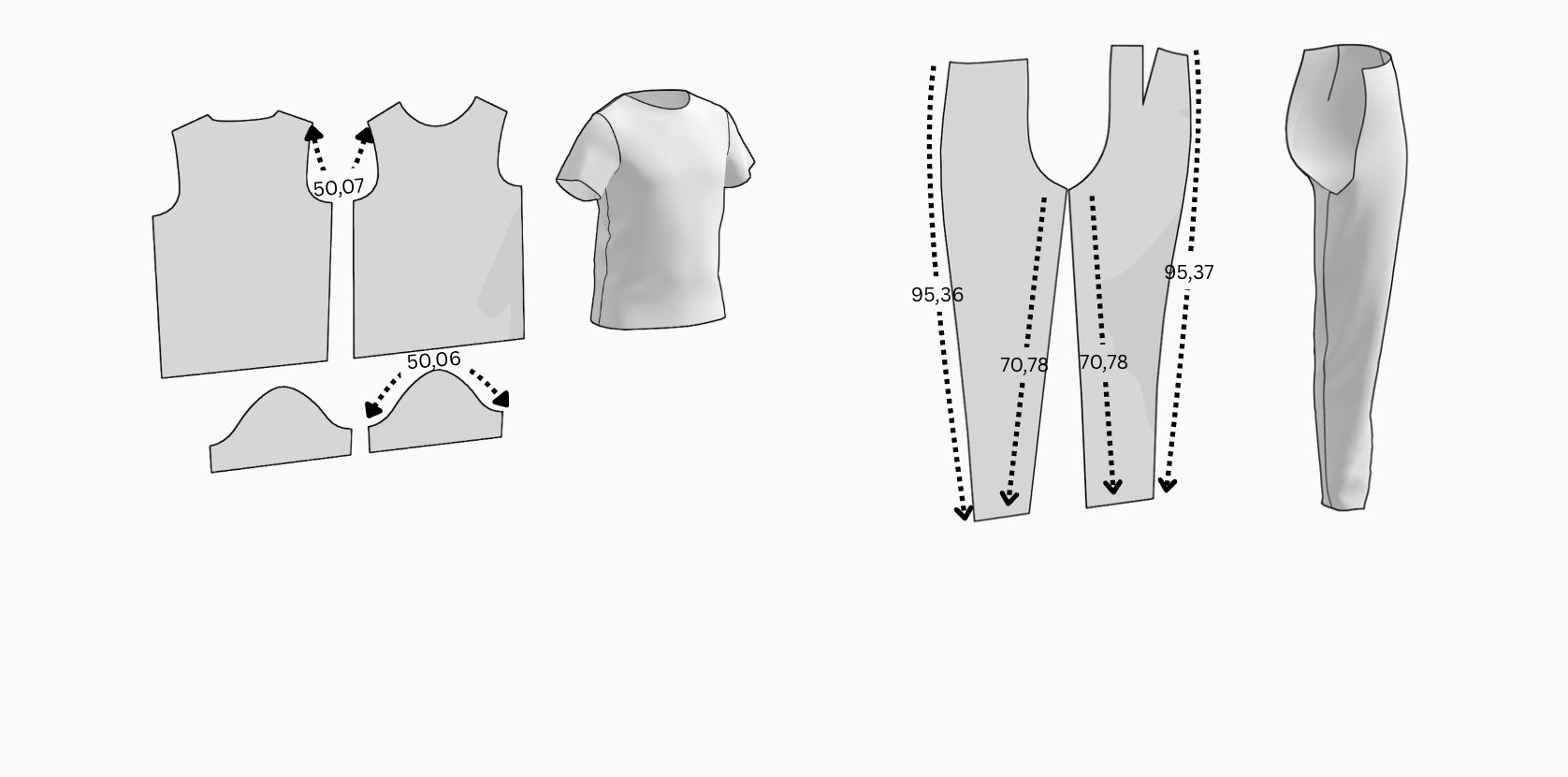

Production-ready patterns from current manufacturer pilot programs, demonstrating complete workflows from reference image to plotter machine.

We're currently running pilot programs with manufacturers implementing complete workflows from reference image to plotter machine using LA VIPÈRE. These aren't lab demonstrations. They're production implementations with real collections, real deadlines, and real manufacturing constraints.

The results validate what we've built: AI-native pattern making fundamentally transforms production workflows in ways traditional CAD cannot match.

What to Consider When Choosing Pattern Making Software

Before diving into specific tools, let's establish the evaluation criteria that matter for professional pattern making:

- Pattern creation workflow: How intuitive and efficient is the pattern drafting process?

- 3D simulation quality: How realistic and accurate is the fabric draping and fit validation?

- Learning curve: How long does it take to become proficient?

- Time-to-market: How quickly can you iterate from concept to production-ready patterns?

- Fit accuracy: How precisely can you validate fit and make adjustments before physical sampling?

- Design flexibility: How easily can you explore design variations and complex constructions?

- Grading capabilities: How does it handle multi-size pattern grading?

- Integration: Does it work with cutting machines, PLM systems, and manufacturing workflows?

- Innovation: Is the platform evolving with AI and automation trends?

Traditional CAD Leaders

CLO3D

Overview

CLO3D has become the industry standard for 3D fashion design, known for its exceptional cloth simulation and visualization capabilities. Originally focused on 3D simulation, it now includes integrated 2D pattern tools.

Strengths

- Photorealistic visualization: Industry-leading rendering quality for marketing and presentations

- Animation capabilities: Can create runway walk simulations and fit videos

- Large user base: Extensive community, tutorials, and third-party support

- Industry adoption: Used by major brands, recognized by manufacturers

Limitations

- Manual pattern creation: 2D pattern tools require traditional pattern making knowledge

- Manual 3D setup: Every simulation requires manual positioning, pinning, and stitching

- Manual grading workflow: Must update, true, and recalculate 3D for each size individually

- Steep learning curve: 3-6 months to proficiency, years to mastery

- Time-intensive: Creating and simulating patterns is still manual and slow

- No AI assistance: No automated pattern generation or intelligent design suggestions

- 2D tools feel secondary: Pattern creation interface not as refined as dedicated 2D CAD

Best For

Designers who already have pattern making expertise and need photorealistic rendering for client presentations and marketing materials. Best when 3D is used for final visualization rather than iterative design workflow.

Lectra Modaris

Overview

Lectra is the enterprise gold standard for production pattern making. Developed over 40+ years, it's deeply integrated into manufacturing workflows worldwide.

Strengths

- Production-proven: Decades of refinement for manufacturing workflows

- Powerful 2D tools: Comprehensive pattern drafting and manipulation features

- Advanced grading: Sophisticated rule-based grading systems

- Manufacturing integration: Seamless connection to cutting machines and PLM systems

- Marker making: Integrated fabric optimization and marker nesting

- Enterprise support: Dedicated support teams and training programs

Limitations

- Outdated interface: UI hasn't evolved significantly in years

- 3D capabilities lag: 3D simulation quality behind CLO3D and Browzwear, limiting fit validation accuracy

- Slow time-to-market: Manual workflows significantly extend development cycles

- Requires expert training: 6-12 months to proficiency impacts team scalability

- No AI innovation: Still relies on manual pattern making methods, limiting design flexibility

- Vendor lock-in: Difficult to migrate away once invested

Best For

Large manufacturers with dedicated pattern making teams and established Lectra infrastructure. Companies prioritizing manufacturing integration over design innovation.

Browzwear

Overview

Browzwear offers a comprehensive suite with strong 3D capabilities and improved 2D pattern tools, positioning itself as a CLO3D alternative with better 2D integration.

Strengths

- Balanced 2D/3D approach: Better integration between pattern and simulation than CLO

- Good simulation quality: Competitive cloth physics and rendering for fit validation

- Cloud capabilities: Better remote collaboration features

Limitations

- Smaller community: Fewer resources and tutorials than CLO3D

- Still manual: No AI-powered automation, limiting design iteration speed

- Learning curve: 4-6 months to proficiency impacts time-to-market for new team members

- Limited flexibility: Manual workflows constrain design exploration

Best For

Mid-size brands wanting better 2D/3D integration than CLO offers, with less enterprise overhead than Lectra.

Optitex

Overview

Optitex provides a full suite from 2D pattern making to 3D simulation, with particular strength in marker making and production optimization.

Strengths

- Strong marker making: Excellent fabric optimization tools

- Modular system: Can purchase only needed components

- Production focus: Built for manufacturing efficiency

Limitations

- 3D quality: Simulation quality below CLO and Browzwear

- Interface: UI feels dated

- Market position: Losing ground to newer competitors

- No innovation: Limited new feature development

Best For

Manufacturers prioritizing marker making and fabric optimization over cutting-edge 3D visualization.

The AI Revolution: Next-Generation Pattern Making

LA VIPÈRE: AI-Native Pattern Making

Overview

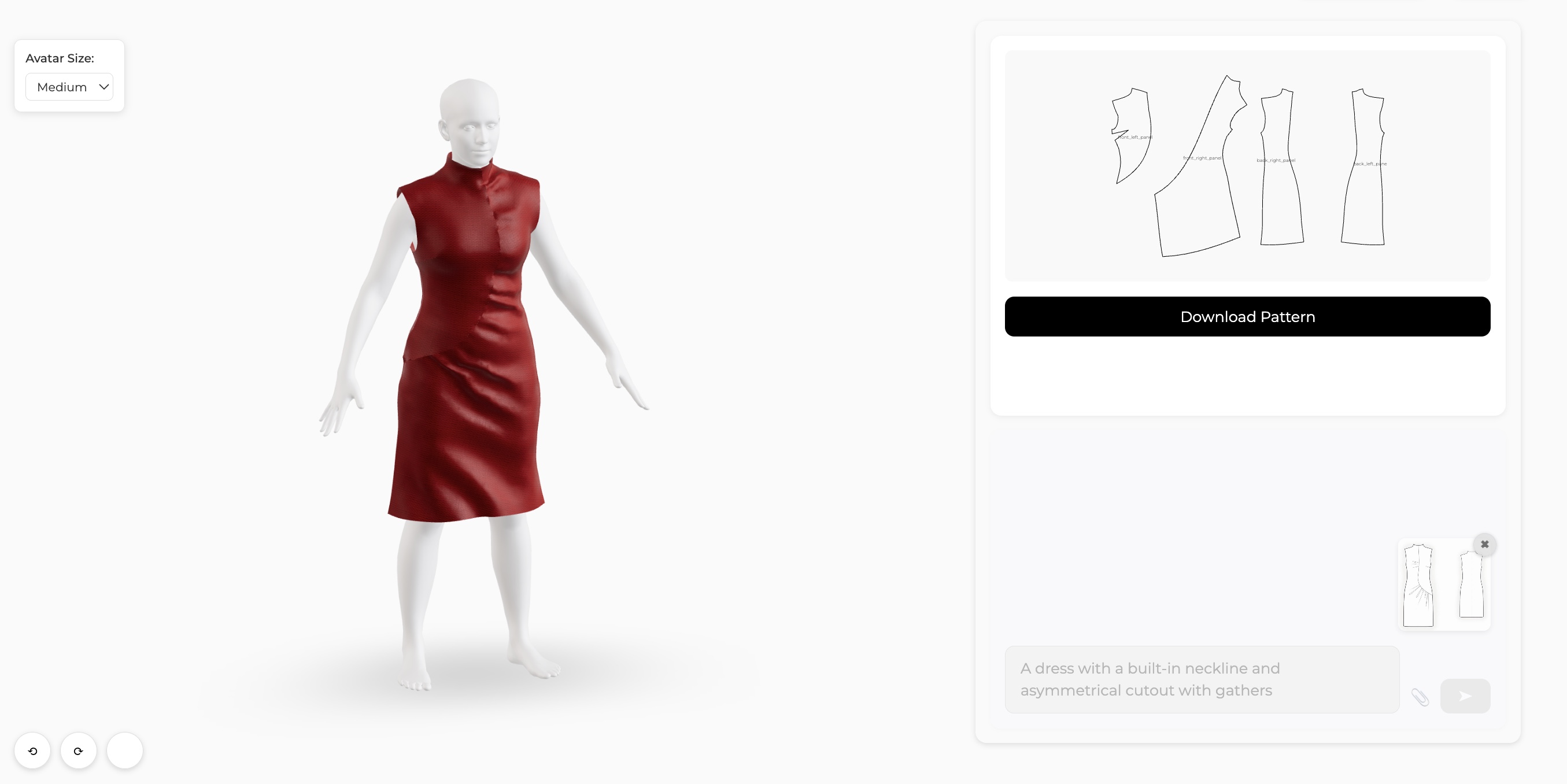

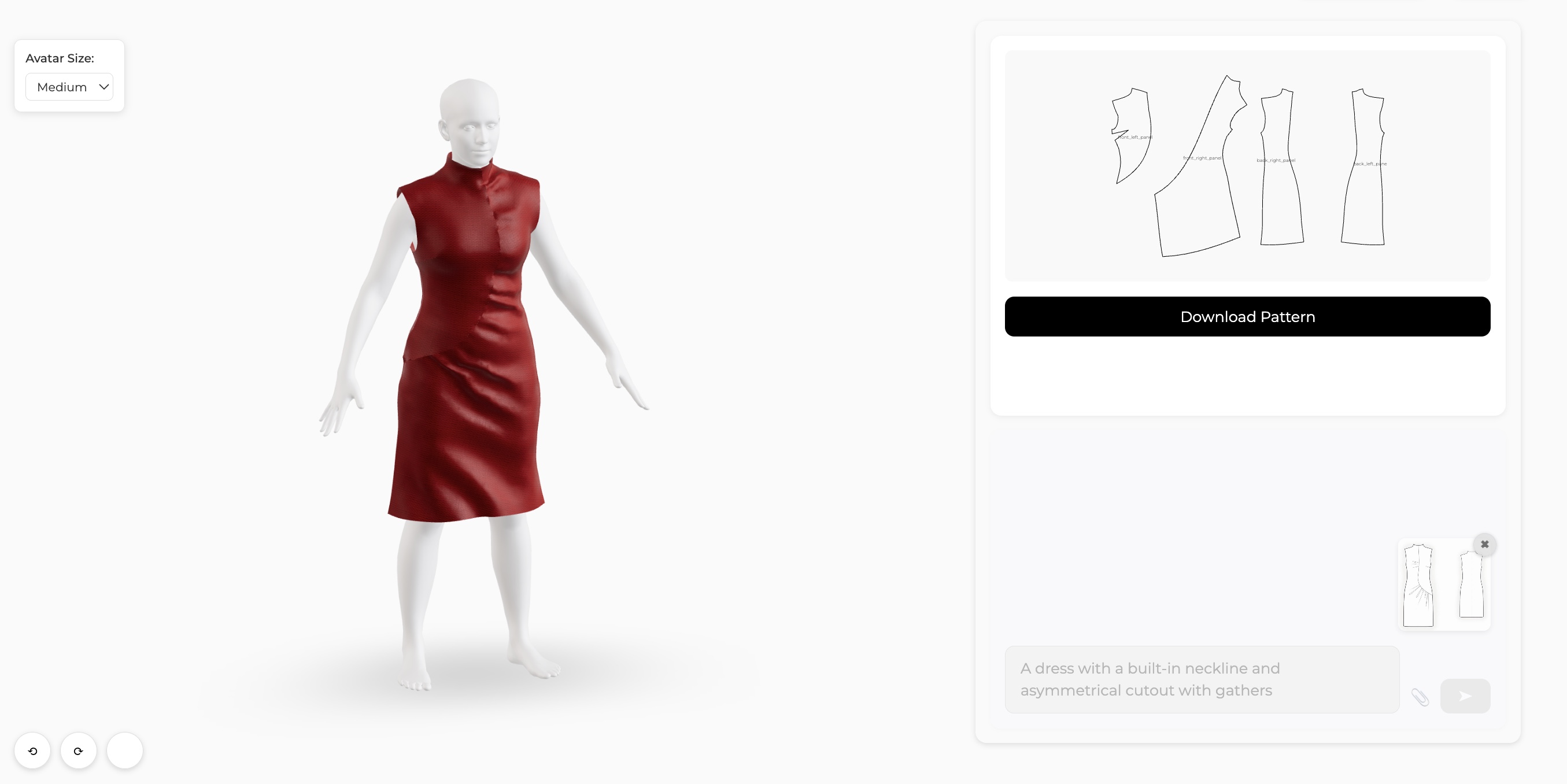

LA VIPÈRE's AI-native platform generates patterns directly from design intent, with automatic 3D simulation on measurement-based avatars.

LA VIPÈRE represents a fundamental paradigm shift: instead of digitizing traditional pattern making methods, it uses geometric AI to generate patterns directly from design intent. Built from the ground up around AI and state of the art mathematical theories and proprietary innovations, it's the first true AI-native CAD for fashion.

Market position: Currently running production pilots with manufacturers and receiving integration requests from major brands who recognize LA VIPÈRE as the market leader in AI-powered pattern making.

The Core Difference

Traditional CAD tools (CLO, Lectra, Browzwear) are digital drafting tables. They give you digital tools to do what you'd do on paper, just faster. LA VIPÈRE is fundamentally different: it's an AI design partner that understands garment construction and generates patterns for you.

Key Capabilities

1. AI Pattern Generation

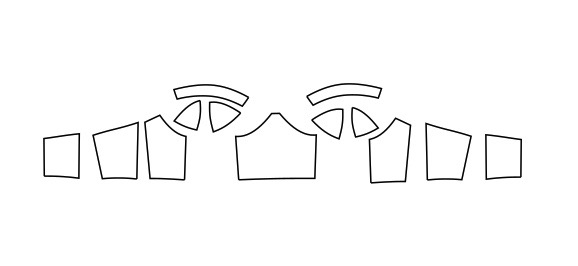

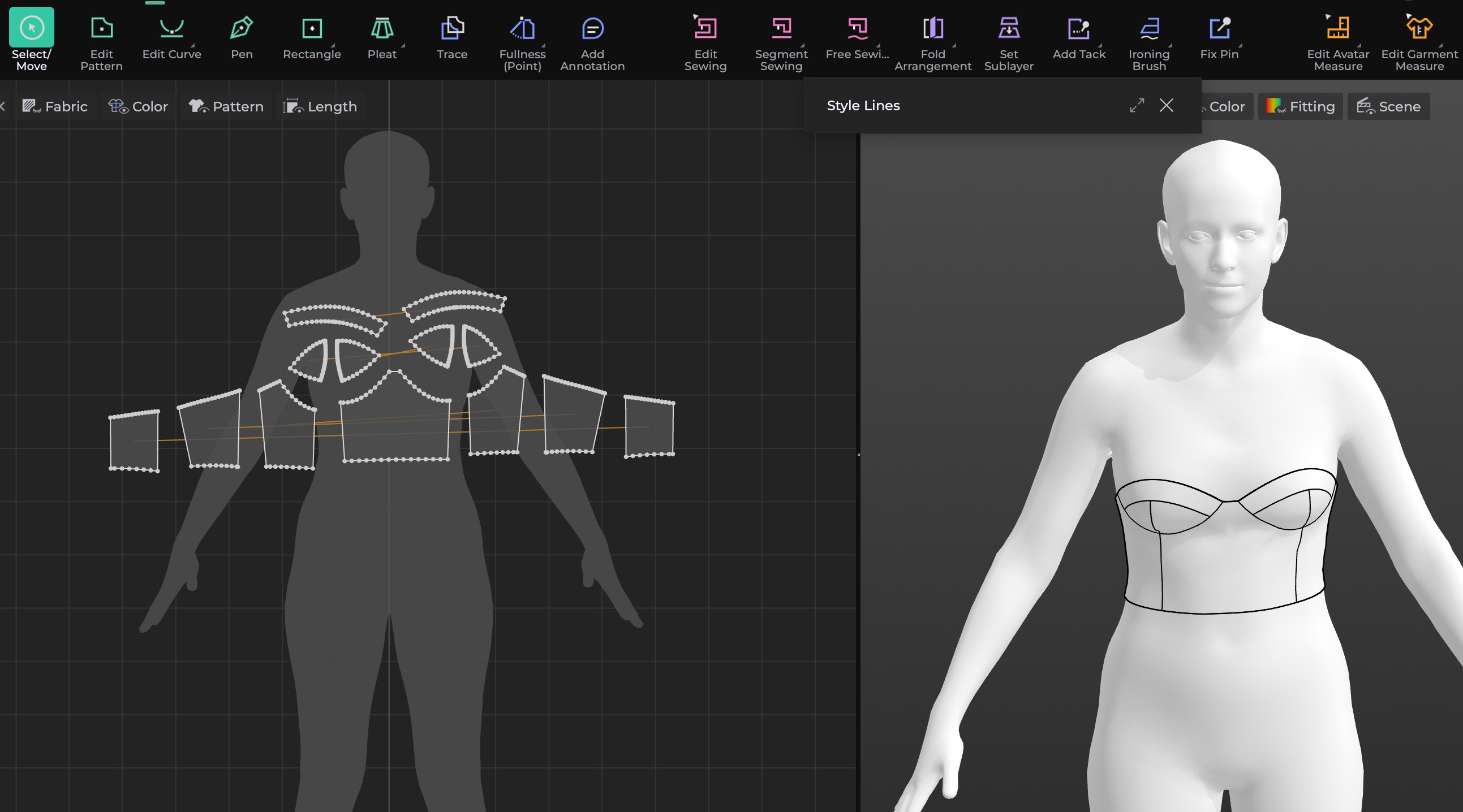

AI generates mathematically precise patterns with matching seams and geometric constraints, ready for production in minutes.

Describe your design or provide a reference image, and the geometric AI generates production-ready patterns. No manual drafting required. See our case study: How to Extract Sewing Patterns from E-commerce Photos. Learn how to write effective prompts: Prompt Guide.

2. Automatic 3D Simulation

Every pattern is automatically simulated in 3D with physics-based cloth simulation. No manual positioning, pinning, or stitching required.

Every generated pattern is automatically simulated in 3D with physics-based cloth simulation. No manual positioning, pinning, or stitching required. The AI instantly places patterns on the avatar, stitches seams, and validates drape. What takes hours of manual work in traditional 3D tools happens automatically in seconds. View 3D examples in our gallery.

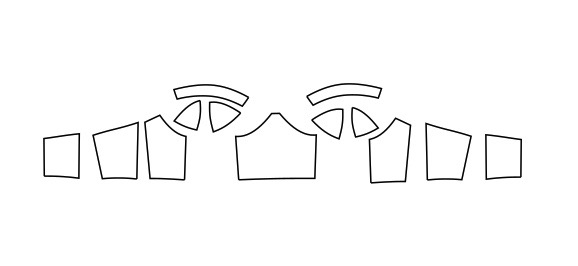

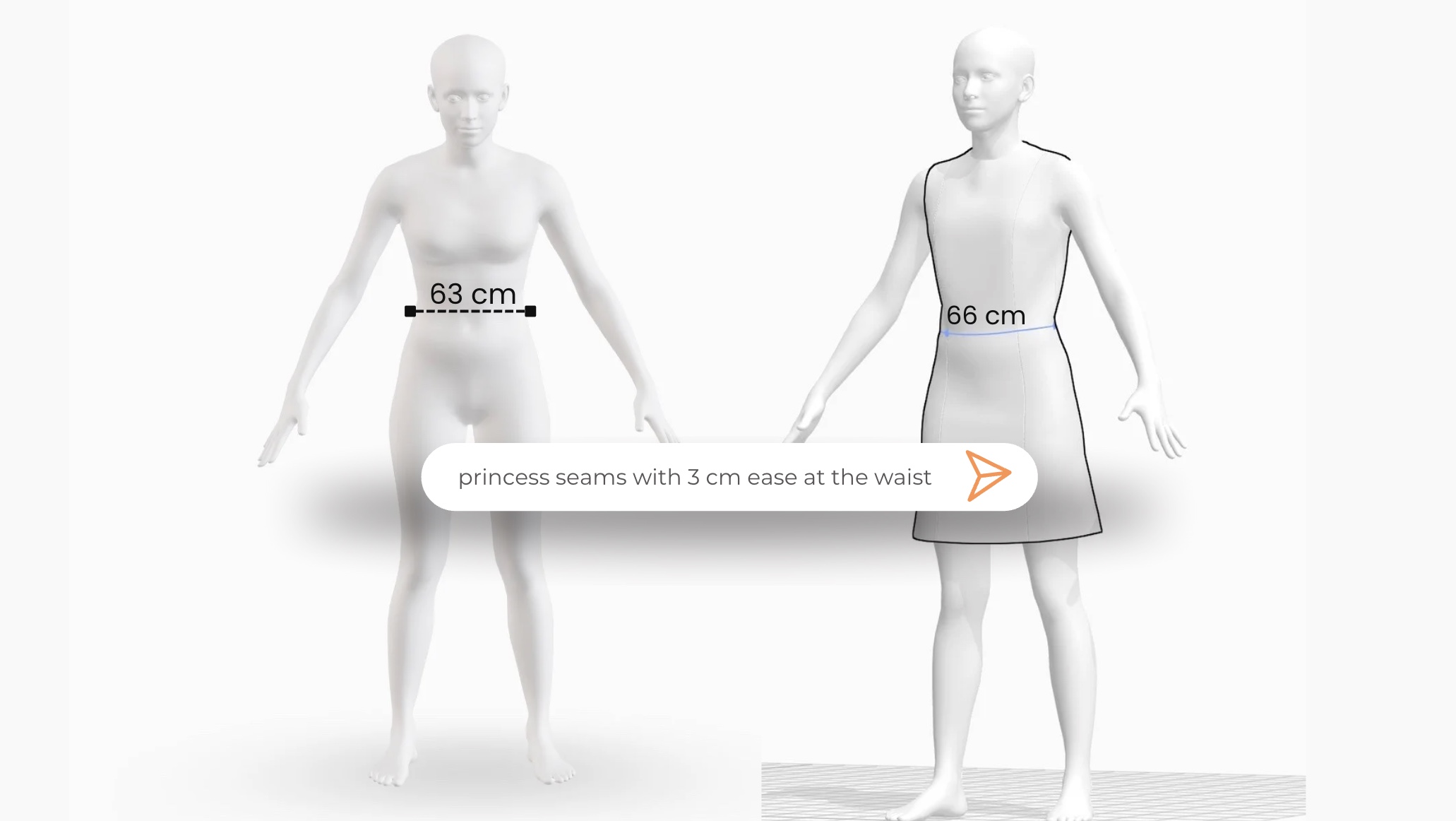

3. Instant Multi-Size Grading with 3D Validation

All sizes are generated and validated in 3D simultaneously. Traditional tools require hours or days of manual per-size updates.

AI generates graded patterns for all sizes simultaneously with instant 3D drape visualization for each size. Traditional tools require manual grading rules, then updating each size individually, truing patterns, and recalculating fit for every size. This process takes hours or days. LA VIPÈRE does this instantly: all sizes generated, all sizes validated in 3D, ready for production. Learn more: Grading Guide.

4. Mathematical Precision

Patterns are generated using state of the art mathematical theories and proprietary innovations, ensuring accuracy exceeding manual drafting.

Patterns are generated using state of the art mathematical theories and proprietary innovations, ensuring accuracy and consistency. Read about the underlying theory: The Mathematics of Pattern Making. See examples of precision in action: Gallery.

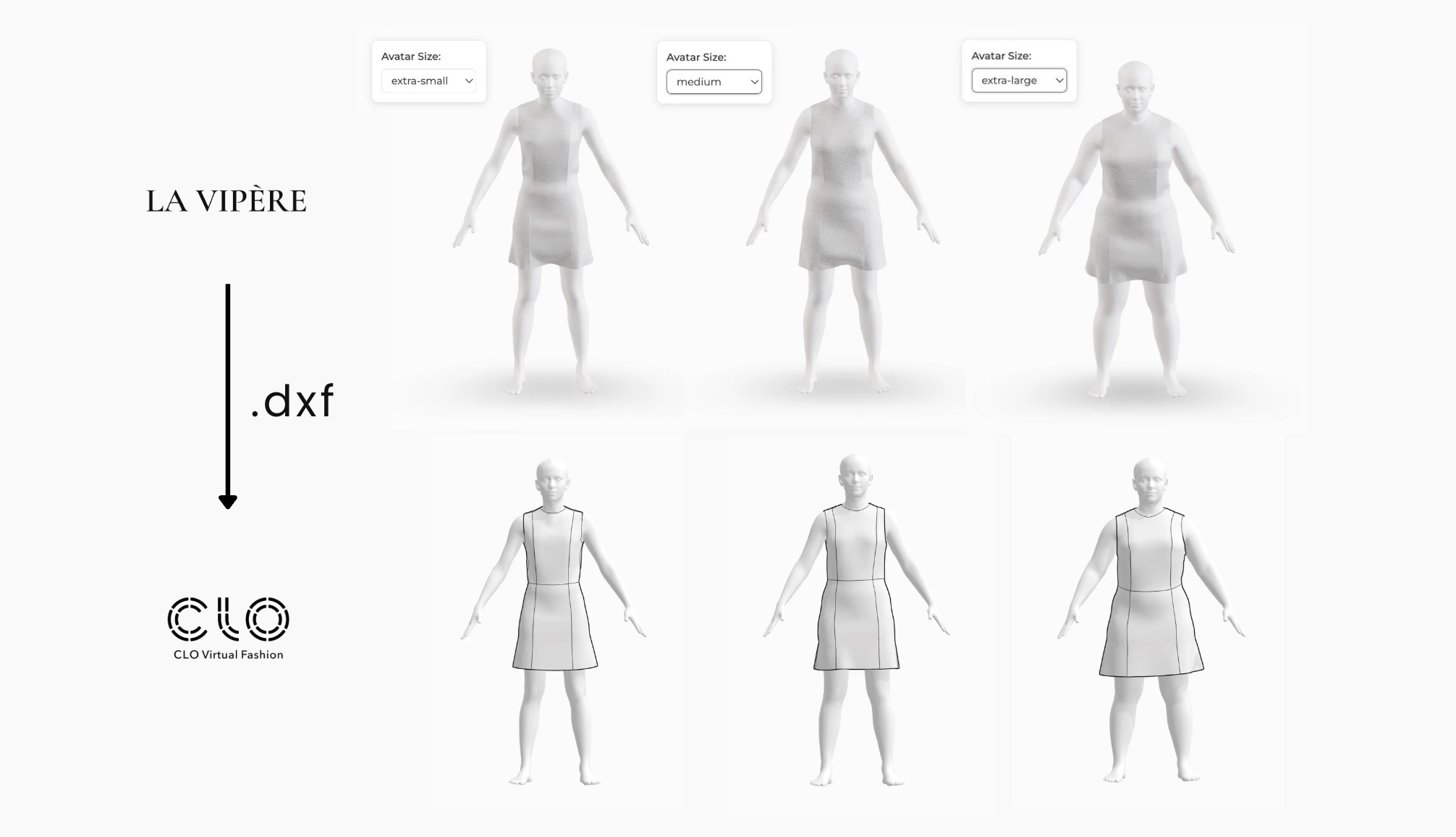

5. Strong Integrations

Seamless DXF export compatible with CLO3D, Gerber, Browzwear, and other production systems. Production-ready patterns integrate directly into manufacturing workflows.

Seamless export to production systems and manufacturing workflows. Production-ready patterns integrate directly into existing cutting and manufacturing pipelines. See export examples: View Gallery.

Strengths

- Unmatched speed: Minutes instead of hours/days to create patterns. 10x to 100x faster than manual workflows

- Automatic 3D simulation: No manual positioning, pinning, or stitching. AI handles everything automatically

- Instant multi-size grading: All sizes generated and validated in 3D simultaneously, not size-by-size manual updates

- AI-powered intelligence: Geometric AI that continuously learns and improves, not static software

- Innovation leadership: Built from the ground up around AI and state of the art mathematical theories and proprietary innovations, not legacy systems retrofitted with automation

- Professional-grade output: Production-ready patterns with mathematical precision exceeding manual drafting

- Zero technical debt: Modern architecture designed for the AI era, not constrained by decades-old codebases

- Strong integrations: Seamless production workflow integration

- Competitive advantage: Early adopters gain years of advantage over competitors still using traditional tools

Current Focus

- Early adopter phase: Platform rapidly evolving with user feedback

- Production readiness: Continuously improving output quality and manufacturing integration

- Complex constructions: Continuously adding support for advanced techniques

Best For

Brands and manufacturers serious about competitive advantage through technology leadership. Companies that understand AI isn't just a feature. It's a fundamental transformation of production workflows. Organizations implementing dual workflows where design teams iterate rapidly while pattern making teams focus on production optimization.

Validated by: Manufacturers currently piloting image-to-plotter workflows, brands requesting production integrations, and fashion professionals at every level from students to industrial pattern makers.

See examples across skill levels: High School Student Creates Hanbok with AI to industrial manufacturing implementations.

Side-by-Side Comparison Matrix

| Feature | LA VIPÈRE | CLO3D | Lectra | Browzwear | Optitex |

|---|---|---|---|---|---|

| Pattern Creation | AI-Generated | Manual | Manual | Manual | Manual |

| 3D Simulation | Automatic | Manual | Basic | Manual | Manual |

| Learning Curve | Days | 3-6 months | 6-12 months | 4-6 months | 4-6 months |

| Time to Pattern | Minutes | Hours-Days | Hours-Days | Hours-Days | Hours-Days |

| Grading + 3D | Instant all sizes | Manual per size | Manual per size | Manual per size | Manual per size |

| Technology Generation | AI-Native | 3rd Gen | 2nd Gen | 3rd Gen | 2nd Gen |

| Integrations | Strong | Strong | Excellent | Good | Good |

| Innovation | AI-first | Incremental | Minimal | Incremental | Minimal |

Use Case Recommendations

For Emerging Designers

Best choice: LA VIPÈRE

If you're starting out or don't have extensive pattern making training, traditional CAD tools will be overwhelming and require months of learning before you can create anything. LA VIPÈRE's AI lets you focus on design vision while handling the technical pattern engineering with professional precision. Get started quickly: Quick Start Guide | See Examples.

For Independent Brands

Best choice: LA VIPÈRE

LA VIPÈRE for rapid pattern generation and iteration. The platform handles everything from initial pattern creation through 3D validation to production-ready exports. Optional integration with CLO3D for photorealistic marketing renders if your visual communication strategy requires it. Explore the Prompt Guide to maximize your design output, or browse gallery examples.

For Established Brands

Best choice: LA VIPÈRE (transformation) or Lectra (status quo)

If you're committed to maintaining market leadership through technology advantage, LA VIPÈRE represents the next generation of pattern making. The value isn't just in time savings. It's in competitive positioning, faster time-to-market, superior fit accuracy through instant 3D validation, and design flexibility to iterate variations that would be prohibitively time-consuming with traditional methods.

Real-world validation: Major brands are already requesting LA VIPÈRE integrations specifically because they recognize the market leadership position and see the dual-workflow advantage. See the full details in the Brand Integrations section.

If you have massive existing Lectra infrastructure and prioritize stability over innovation, maintain your current systems. But understand your AI-adopting competitors are accelerating past you in time-to-market and design capabilities.

For Large Manufacturers

Best choice: LA VIPÈRE with existing system integration

Current pilot programs demonstrate LA VIPÈRE integrating with existing manufacturing systems, from reference image all the way to plotter machine output. This isn't theoretical. It's being validated in production environments right now.

The workflow: maintain your existing Lectra infrastructure for final production files if needed, but use LA VIPÈRE for the entire development cycle. Pattern makers increase capacity 5-10x by using AI for base generation and focusing their expertise on production optimization.

Based on our factory floor experience, this represents the future of garment manufacturing: AI handling repetitive generation, human expertise handling optimization and refinement.

For Design Schools

Best choice: LA VIPÈRE

Teaching traditional CAD tools means students spend months learning software instead of developing design skills. LA VIPÈRE lets students focus on creativity, design thinking, and garment construction principles rather than manual drafting mechanics.

Why Brands Are Requesting LA VIPÈRE Integrations

Major fashion brands are actively requesting workflow integrations with LA VIPÈRE. They recognize we're the market leader in AI-powered pattern making, and they see two critical use cases:

1. Design Team Workflow: Rapid Iteration Without Bottlenecks

Design teams use LA VIPÈRE to quickly explore design ideas without consuming pattern making capacity. Instead of waiting days for pattern makers to translate sketches, designers generate patterns instantly, validate in 3D, and iterate freely. Only final designs go to the pattern making team for production refinement.

1. Image to Pattern

AI generates production-ready patterns in minutes

2. Pattern to 3D Simulation

Automatic 3D validation with real fabric simulation

3. Export to 3D Software

Direct export to Style3D, CLO3D, Browzwear

Complete workflow: Image → Pattern → 3D Simulation → Export in under 10 minutes

See how fast and easy it is to use LA VIPÈRE: Quick Start Guide | View Gallery Examples

Impact: Design teams can explore 10x more variations in the same timeframe. Pattern makers focus on production optimization rather than translating every design concept.

2. Pattern Making Team Workflow: Accurate Patterns at Scale

Consistent seam quality across all patterns and sizes. Algorithm-optimized for straighter seams and matching seam lengths by default.

Pattern making teams use LA VIPÈRE to generate accurate base patterns for collections rapidly, then apply their expertise to production-specific refinements. The AI handles the time-consuming base pattern generation and multi-size grading with instant 3D validation, while pattern makers focus on manufacturing optimization, fabric-specific adjustments, and quality control.

Impact: Pattern making teams increase output capacity 5-10x, handling larger collections in shorter timeframes while maintaining quality and accuracy.

This dual workflow, where AI handles rapid generation and human expertise handles refinement, represents the future of fashion production. Brands requesting these integrations understand that competitive advantage comes from combining AI speed with human expertise, not choosing one over the other.

The Future: Why AI Will Win

The pattern making software market is at an inflection point. Traditional CAD tools digitized manual processes, but they didn't fundamentally change the workflow. You still need years of training. You still manually draft every line. You still spend hours on each garment.

AI changes everything:

- Competitive advantage: Early adopters gain years of market positioning advantage

- Speed multiplier: 100x faster iteration from concept to production

- Automation superiority: AI handles 3D simulation, grading, and validation automatically. No manual positioning, pinning, or per-size updates required

- Innovation enablement: Explore design possibilities that were economically infeasible with manual workflows

- Quality consistency: Mathematical precision exceeding manual drafting capabilities

- Rapid proficiency: Days to productivity instead of years of training investment

- Continuous improvement: AI systems evolve and improve, legacy tools remain static

- Market disruption: AI-first companies will outpace traditional CAD users

The question isn't whether AI will dominate pattern making. It's whether you'll be an early adopter gaining competitive advantage or a late follower playing catch-up.

The evidence is clear: Manufacturers are piloting AI workflows in production. Brands are requesting integrations. Pattern makers are increasing output 5-10x. Design teams are exploring 10x more variations. This isn't the future. It's happening now.

What Traditional CAD Vendors Are Missing

CLO, Lectra, and others are incrementally adding "AI features", usually just automation of specific tasks. But they're constrained by their legacy architecture. True AI-native design requires building from the ground up around geometric AI and state of the art mathematical theories and proprietary innovations, not bolting AI onto decades-old manual workflows.

By the time traditional vendors rebuild their platforms around AI (if they ever do), AI-first companies like LA VIPÈRE will have years of advancement and data advantage.

Making Your Decision

The right pattern making software depends on your specific situation:

Choose traditional CAD (CLO, Lectra, Browzwear) if:

- You have existing infrastructure and trained staff on these platforms

- You need photorealistic marketing renders (CLO excels here)

- You're a large manufacturer with deep Lectra integration

- You prioritize stability over time-to-market advantages

- Your competitive strategy doesn't depend on design iteration speed

Choose LA VIPÈRE if:

- You're committed to maintaining competitive advantage through technology leadership

- Time-to-market is critical to your competitive strategy

- You need superior fit accuracy through instant multi-size 3D validation

- Design flexibility and rapid iteration are essential to your business model

- You understand AI is a strategic investment in competitive positioning

- You're ready to lead the industry transformation rather than follow it

- You want patterns with mathematical precision in minutes, not days

- Your team needs to scale design output without proportionally scaling headcount

The fashion industry is being transformed by AI. The tools that dominate today won't necessarily dominate tomorrow. Make sure you're building on the future, not the past.